INSIDE: EARTHQUAKER DEVICES

“Be fair, do good work, and stand behind it forever.”

Earthquaker Devices began as many effects brands do, with one guy and a broken overdrive pedal. But that guy, Jamie Stillman, would spend years ensuring that Earthquaker Devices would never become just another effects brand.

Built upon strong DIY ethics and a refusal to bow to to anyone, Earthquaker makes the pedals they want the way they want, with an emphasis on ethical work practices and, most importantly, fun.

We spoke to Stillman about ‘90s punk rock, intersecting passions, and everything that makes Earthquaker Devices extra special. How we got onto Riki Rachtman is a question for another time.

Q&A WITH JAMIE STILLMAN

What is Earthquaker Devices?

EarthQuaker Devices makes extra-special guitar effect pedals by hand.

Who is Earthquaker Devices?

EarthQuaker Devices was started by me (Jamie Stillman) as a hobby that accidentally

turned into a real business. It is currently run by myself and my wife, Julie Robbins. We employ over 50 people and operate out of a 15,000 square foot building located in beautiful downtown Akron, Ohio.

Key Players:

Jamie Stillman- Founder/Product Designer/President

Julie Robbins- CEO

Luke Zollinger- COO

Karl Vorndran- Sales Manager

Cory Juba- Product Manager

Jeff France- Production Manager

Mike Tolan- Production Manager

Mike Stangelo- Production Manager

Brad Thorla- Inventory Systems Manager

Anna Blumenthal- Sales & Artist Relations

Taka Tozawa- EarthQuaker Japan

Uri Garcia- Social Meda/Copywriter/Artist Relations

Chris Tran- Videographer

Geoff Crowe- Art Director

Matt Horak- Illustrator

How did you get started building effects?

I had a broken DOD250 overdrive pedal that was in need of repair. I looked up the

schematic and found a website called generalguitargadgets.com, and that got me hooked. I started building pedals for myself and my friends, and it just kind of took off from there.

When and how did Earthquaker Devices begin?

2004/2005-ish depending on who you ask. It became my full-time job in 2008. I hired my first employee in 2010. Julie came on full time in 2012, and that is when EQD really started growing.

What inspired you to begin, and what inspires you to continue?

I really only wanted to play music, but I also liked to tinker and do graphic design. Building pedals combined all three of my interests into one neat little package, so it seemed like it would be a good idea. Creating new sounds is what continues to inspire me.

How would you describe an Earthquaker Devices effect to someone new to the

brand?

Julie likes to say, “half our line could replace the pedals you used to write your last record, and the other half will inspire you to write your next” or something to that effect. I think that’s a pretty accurate description. To paraphrase Riki Rachtman: “One foot in the past, one fist in the future.”

How is an Earthquaker Devices effect constructed from start to finish?

All the parts are stuffed by hand, usually in panels of 4-6 boards, then they go on to the dipping stage. We used to solder each point one at a time, but we changed to a solder bath a few years ago. It speeds up the process and it creates a more reliable solder joint. After dipping, they are inspected and then run through the lead cutter, and then on to cleaning and drying. From there, they go to the QC stage where all the pots, jacks, wires, and any other parts that can’t be dipped are applied, and then everything is inspected. Next is assembly, where the boards are inserted into the enclosure and it starts to resemble a pedal. From assembly, they go to testing where knobs are applied, wires are wired, and a real-life human plays through the pedal and makes sure it works as it should and there are no defects in the final assembled pedal. The approved pedals move on to boxing where they are serialized, occasionally doodled in, boxed, and put on the shelf for order fulfillment. While all of this is happening, the raw enclosures are being drilled out by a combination of CNC and hand-drilling. After they are drilled, they get sent out for powder coating. This is one of the few things we don’t do in-house. After the enclosures come back from powder, they are printed on UV printers then put on the shelf where they wait to become finished pedals.

What components, designs, techniques, etc. make Earthquaker Devices effects unique?

Aside from the few pedals that use carbon comp resistors and the occasional

germanium transistor, we don’t typically use highly specialized parts. We stick mainly to metal film resistors and caps, readily available through-hole transistors, SMT op-amps, and other easy to source parts. I think what makes EQD pedals unique is the same thing that makes any other small builders pedals unique: designers’ vision and execution. I have my tastes and my own ways of voicing things just like anybody else. I don’t really worry about the market, or if what I’m making is useful to everyone, I’m just trying to make things that I think are cool, and hopefully, other people will like it too.

How long does it take to make an Earthquaker Devices effect start to finish?

For assembly, that varies depending on what model it is. Some can take 30 minutes; some can take over an hour. As for design, I would say 3-6 months on average until I am happy with the final results. Some pedals have gone really quick, like a week, and there are others I’ve been working on for almost ten years.

What is the spirit of Earthquaker Devices?

Pretty much all of us are self-taught at what we do, so there is a very heavy DIY spirit at EQD. I came from a 90’s punk rock background. The Dischord records ethic has stuck with me. I think it’s a permanent part of EQD. No matter how big we get or how many people we employ, it must be done ethically, and it should be fun.

What is the Earthquaker Devices mission?

To be fair, do good work, and stand behind it forever.

Where does Earthquaker Devices go from here?

Forward in whatever direction/way we see fit…then retire to an island and never think

about guitar pedals ever again.

SHOP EARTHQUAKER DEVICES

Related Posts

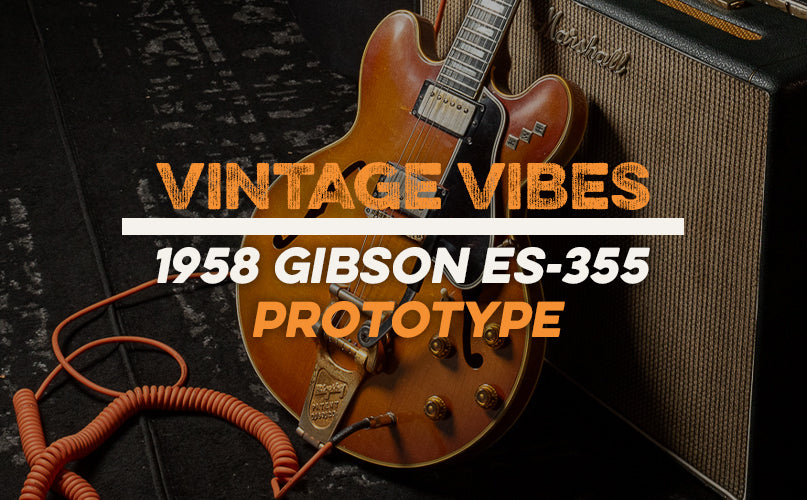

Vintage Vibes | 1958 Gibson ES-355 Prototype

Of all the guitars we’ve ever had in the Chicago Music Exchange Vault, the prototype 1958 Gibson ES-355 remains one of the most playable vintage guitars we’ve ever had! Learn all about...

Read moreTeenage Engineering | EP-133 K.O. II Sampler

The best-selling Pocket Operator from Teenage Engineering has just gone pro, and it’s now available at Chicago Synth Exchange! Based on the Teenage Engineering PO-33 K.O—“PO” being shorthand for the...

Read moreGibson Custom Shop | Limited Edition 1959 Les Paul Standard Reissue Murphy Lab Aged

Pick your favorite finish from among the FIRST-EVER Gibson Guitar Murphy Lab Brazilian Rosewood Limited Run Les Paul Standard Models at Chicago Music Exchange! Only 50 guitars will be made for...

Read more